An ink stick is made of natural ingredients, such as soot (lampblack of pine, sesame oil, colza oil, etc), animal glue and perfumes (acting mainly as preservatives). For this reason special handling needs to be applied in order to prolong its life span and sustain its quality.

First of all, ink should be kept in a dry environment away from moisture. For that reason, good quality ink comes with a wooden box (usually made of Paulownia tree), wrapped in Xuan paper (宣紙, Chinese calligraphy paper) or washi (和紙, Japanese paper). It also must not be exposed to excessive heat or cold, or direct sunlight.

Before grinding the ink on the inkstone, its tip should be soaked in water for 30 seconds or more, to soften it and prevent scratching of the inkstone surface or chipping of the ink stick. Ink should be ground in circular movements on the “inkstone’s temple” (墨堂, bokudou), by adding few drops of water. When desired ink thickness and colour is achieved, it is to be pushed down to the “inkstone’s well” (墨池, bokuchi). We can then add more water and repeat the process.

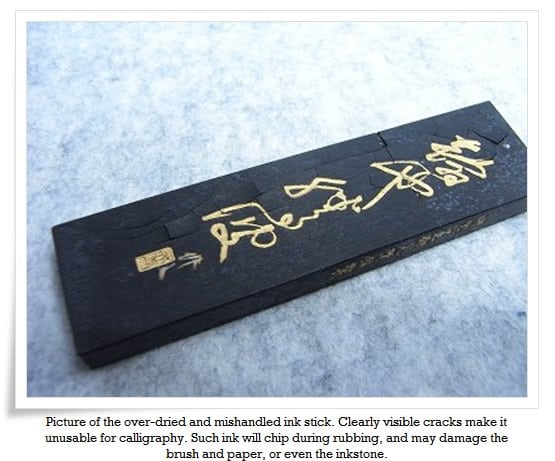

After we have finished grinding ink for the day, the ink stick should be wiped clean with paper and dried, then wrapped and placed back in the protective box.

Pouring too much water on the inkstone will negatively affect both its colour and texture, resulting in undesired ink blurring effects and poor ink spreading ability, etc. Pressing ink too hard will shred larger particles and undesirably change consistency and texture of the ink liquid. An old saying goes that the ink stick should be wielded with a force of a withered man, and brush with a force of a warrior.

In summary, it is not only crucial what type of ink we buy, but also the quality of the water, inkstone, then brush, paper and finally the skills of the calligrapher himself that allow for creating a great calligraphy piece. If one of these factors is lacking, the final result will be rather poor.